Navid Soltani Hafshejani, M.Sc.

About me

My research

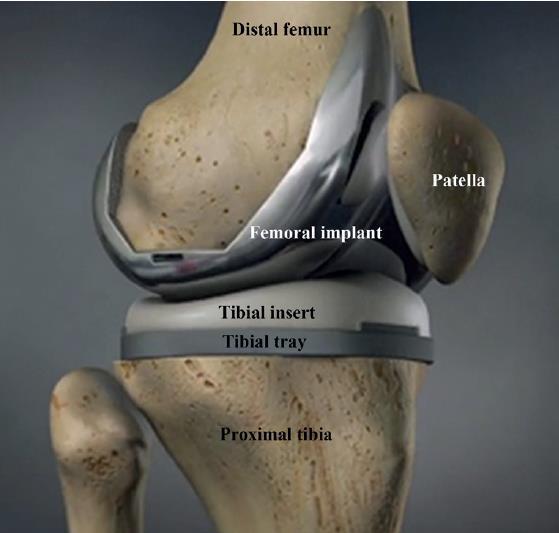

Total knee replacement is an alternative treatment to knee joint defects and nowadays it becomes more acceptable as new designs of implants are developed. However, like other treatments, there are always some factors that may affect the desired outcome of the knee replacement surgery which cause severe pain and dissatisfaction to the patients. In order to pain relief or failure correction of the primary total knee arthroplasty (TKA), revision surgery is suggested which has a lot of complications and costs.

The aim of this project is to develop a computational study of the mechanical effect of TKA failure mechanisms in order to improve the knee replacement method, leading to increase the reliability of the knee prosthesis and decrease the revision complications.

Total knee replacement is an alternative treatment to knee joint defects and nowadays it becomes more acceptable as new designs of implants are developed. However, like other treatments, there are always some factors that may affect the desired outcome of the knee replacement surgery which cause severe pain and dissatisfaction to the patients. In order to pain relief or failure correction of the primary total knee arthroplasty (TKA), revision surgery is suggested which has a lot of complications and costs.

The aim of this project is to develop a computational study of the mechanical effect of TKA failure mechanisms in order to improve the knee replacement method, leading to increase the reliability of the knee prosthesis and decrease the revision complications.